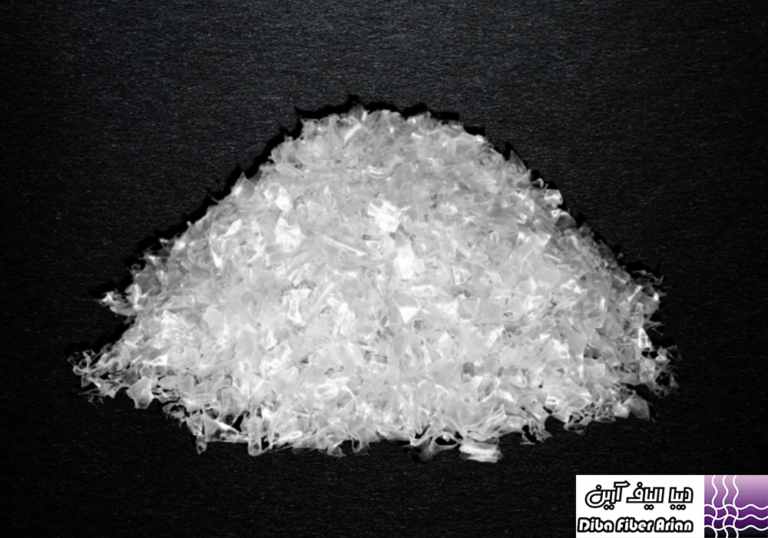

Pet Flakes

Flake or Hot Wash Flakes is a substance that comes from recycling PET bottles. In this way, after separating from food and waste, They will be crushed and finally turned into flakes.

Pet Flakes

disposable bottles that are made of PET, such as bottles of drinks, dairy products, mineral water, etc., are called Flake after being collected and separated. Flake are washed and disinfected in hot wash machines after removing the lid and label. According to production quality, impurities, quality and uniformity of color, manufactured feathers are used as raw materials in various industries. Among the industries in which recycled Flake is widely used, we can mention polyester fiber production and PET sheet production

Flakes(feather); Raw materials for the production of polyester fibers

In general, two types of raw materials are used in the production of synthetic fibers; Petrochemical production granular materials with textile grade (Textile Grade PET) and recycled materials. Fibers produced from petrochemicals are called virgin fibers. Recycled raw material or flake the largest volume of polyester fiber raw material. Fibers produced with recycled materials are called recycled fibers

What is PET

PET or polyethylene terephthalate is a type of polymer that is formed from two types of monomers named terephthalic acid and glycol. This material has been used for the production of food packaging containers and textiles for a long time and has been able to be used due to various features such as easy transportation, transparency, high impact resistance, light weight, suitable flexibility, Maintenance The appropriate amount of gases and moisture obtained by drinking materials, the cost-effectiveness of the amount of energy needed in production, etc, will gain a special place in various industries

Due to the high demand for the use of PET in various industries and to reduce environmental pollution; The recycling of these materials has been expanded in the form of Flakes production

What is hot wash Flakes

Flake or Hot Wash Flakes is a substance that comes from recycling PET bottles. In this way, after separating from food and waste, They will be crushed and finally turned into flakes. These milled bottles are packaged by hot wash machines, passing through tanks containing chemical compounds and disinfectant boiling water, and after passing through a centrifuge for removal

Considering that the incoming bottles to the hot wash lines are a combination of colored and transparent bottles, a combination of different colors will be hot washed in the output product. To separate colored flakes from transparent flakes, from sorting machines to the final product, based on color and consumption, it is classified and supplied in various industries. Another way to produce color flake is to separate and wash PET bottles upon entering the hot wash process. Every day, a significant amount of these flakes after passing the necessary processes are converted into high-quality synthetic fibers in the Diba fiber factory

Read this article to learn how polyester fibers are produced

The quality of these flakes depends on the production process in addition to the quality of the bottles that has been used, The health of this production process depends on factors such as: washing water temperature, accuracy in separating impurities, etc

For example, the presence of PVC more than the allowed limit, due to the high similarity of this material to PET in terms of transparency and appearance; It may cause problems in the production process of synthetic fibers. Diba Fiber Arian Company has been able to supply high quality fibers to its customers by complying with strict standards in providing the needed flake for the production line

Flakes purity measurement criterion

Flake contamination depends on several factors, especially the amount of PVC in PET. In the production of hot wash flake, the amount of PVC is very important and the quality of PET is evaluated with it. Impurity and pollution in hot-washed Flake is mainly due to the presence of PVC, although other compounds such as other polymers and metals also affect the quality of flake. The index determined to measure the purity of these flakes indicates the amount of PVC in the flake and we show it in ppm

Devices needed to produce flake

Floating Tank(Plastic Scrab Washing Machine)

One of the devices whose presence is vital in the PET recycling process is called the Floating Tank device. The function of this machine is to completely wash and separate labels and tags from bottles. When recycling PET, the label and cap must be separated from the PET bottle, which part of this is done by the Floating Tank machine

Small fins are placed on the Float Tank of the tank, which transfer the unusable parts that affect the purity of the hot wash to a smaller tank that is installed in the vicinity of the machine. These parts, which include bottle cap and labels, are sold to other industries after being collected as a by-product of the Perak production line

sand grabber (flakes sand trap)

Another vital device in the flakes production process is the sand grabber machine. The main task of this device is to separate the remaining PVC adhesives on the PET bottles, which have decreased their adhesion to the bottles during the hot wash process, and they are completely separated in this section. The presence of this device has a significant impact on raising the quality level of flakes

Conclusion

As mentioned, the need for recycled products in today’s world is increasing. One of the ways to respond to this need is to use recycled materials such as Flakes (Flake) and turn them into products such as synthetic fibers. At Diba Fiber Arian Factory, we use high-quality hot wash flakes and carry out special processes under the supervision of experts; We convert these flakes into a variety of high quality hollow and solid polyester synthetic fibers

Recycled flakes from PET bottles are very practical and utilisable and economical, and in the future, the demand for this product will undoubtedly increase. flake is used as a basic raw material in the production of polyester fibers. It is interesting to know that flakes with a high quality level and PVC content below 50 ppm are used in the production of high tenacity cotton type fibers, which are used as raw materials in the spinning industry to produce yarn. This issue itself shows the importance of producing high-quality flakes for use in various industries