Manufacturing method of Hollow Fibers

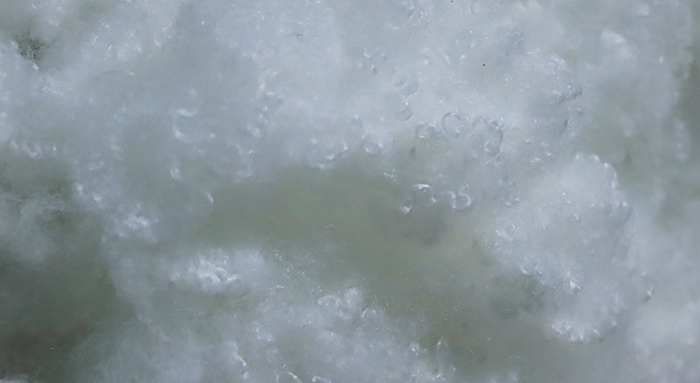

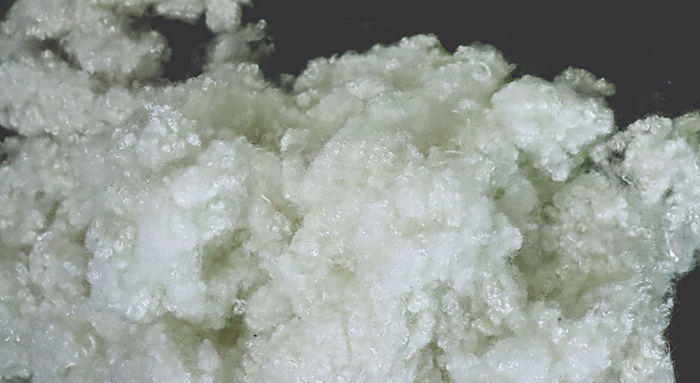

Hollow fiber is made by melt spinning process. In Diba Fiber Arian Company, this type of synthetic polyester fiber is produced by melting PET followed by extruding through spinnerets in order to form long threads. In the next step, these long threads are cooled and harden to form fiber. Finally, the fiber is cut to desired length.

Diba Fiber Arian Company, as a leading manufacturer of synthetic polyester fiber in Iran, produce both silicon (HCS) and non-silicone hollow conjugated fiber (HC). We produce HC/HCS fiber in different denier from 7D to 18D and different cut length from 32mm to 125 mm.

Where to buy synthetic polyester fiber in Iran? If you are looking for best quality and best price of hollow fiber (HCS/HC) in Iran, you can send your inquiry to Diba Fiber Arian Company. We will offer you best quality and best possible price of hollow conjugated siliconized fiber.

Industry

Furniture Industry

Quilt, Mattress and Pillow Industry

Mattress and Cushion Industry

Wadding Industry

Filling Industry

Winter Clothing Production Industry

Types of Hollow Fibers products based on Denier

- HCS Recycle 7D*64mm

- HCS Virgin 7D*64 mm

- HCS Recycle 15D*64 mm

- HCS Virgin 15D*64 mm

Features

HCS Virgin 7D*64 mm

| RANGE | UNIT | TEST |

|---|---|---|

| 7.0±0.7 | gr/9000m | Denier |

| 65.0±5.0 | cm3/gr | BULK |

| 15.0±2.0 | % | REVERSIBLY |

| 95.0±5.0 | % | WITHSTAND PRESSURE |

| 2.0±0.2 | % | SILICON RATE |

| <200 | mgr/100gr | DEFECTS |

HCS Recycle 7D*64mm

| RANGE | UNIT | TEST |

|---|---|---|

| 7.0±0.7 | gr/9000m | Denier |

| 70.0±5.0 | cm3/gr | BULK |

| 15.0±2.0 | % | REVERSIBLY |

| 95.0±5.0 | % | WITHSTAND PRESSURE |

| 2.0±0.2 | % | SILICON RATE |

| <350±50 | mgr/100gr | DEFECTS |

HCS Recycle 15D*64 mm

| RANGE | UNIT | TEST |

|---|---|---|

| 15.0±1.0 | gr/9000m | Denier |

| 70.0±5.0 | cm3/gr | BULK |

| 15.0±2.0 | % | REVERSIBLY |

| 95.0±5.0 | % | WITHSTAND PRESSURE |

| 1.8±0.2 | % | SILICON RATE |

| 400±50 | mgr/100gr | DEFECTS |

HCS Virgin 15D*64 mm

| RANGE | UNIT | TEST |

|---|---|---|

| 15.0±1.0 | gr/9000m | Denier |

| 65.0±5.0 | cm3/gr | BULK |

| 15.0±2.0 | % | REVERSIBLY |

| 95.0±5.0 | % | WITHSTAND PRESSURE |

| 2.0±0.2 | % | SILICON RATE |

| <200 | mgr/100gr | DEFECTS |