Price of Polyester Fiber in Iran

The price of synthetic fiber in Iran depends on factors such as raw material costs, production and energy costs, transportation costs, market demand, competition among manufacturers, the quality of the fiber

The Price of Polyester Fibers in Iran

Introduction

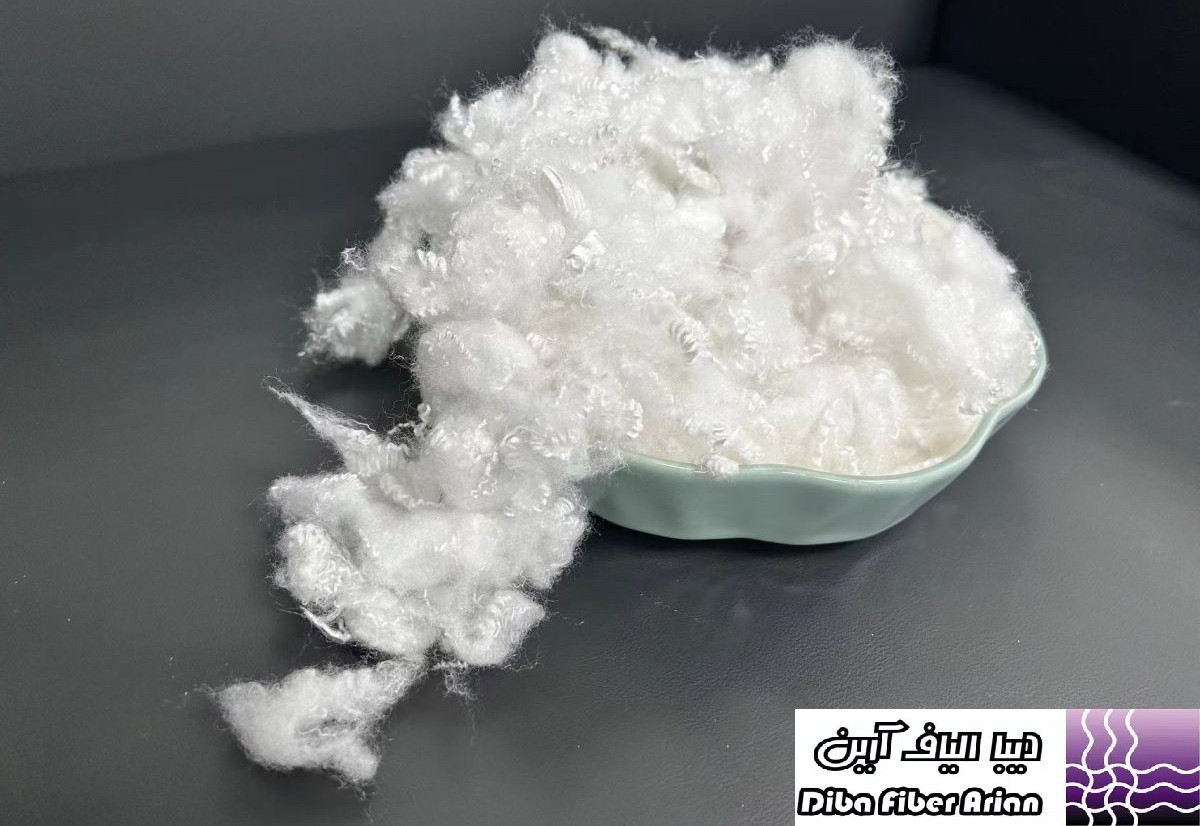

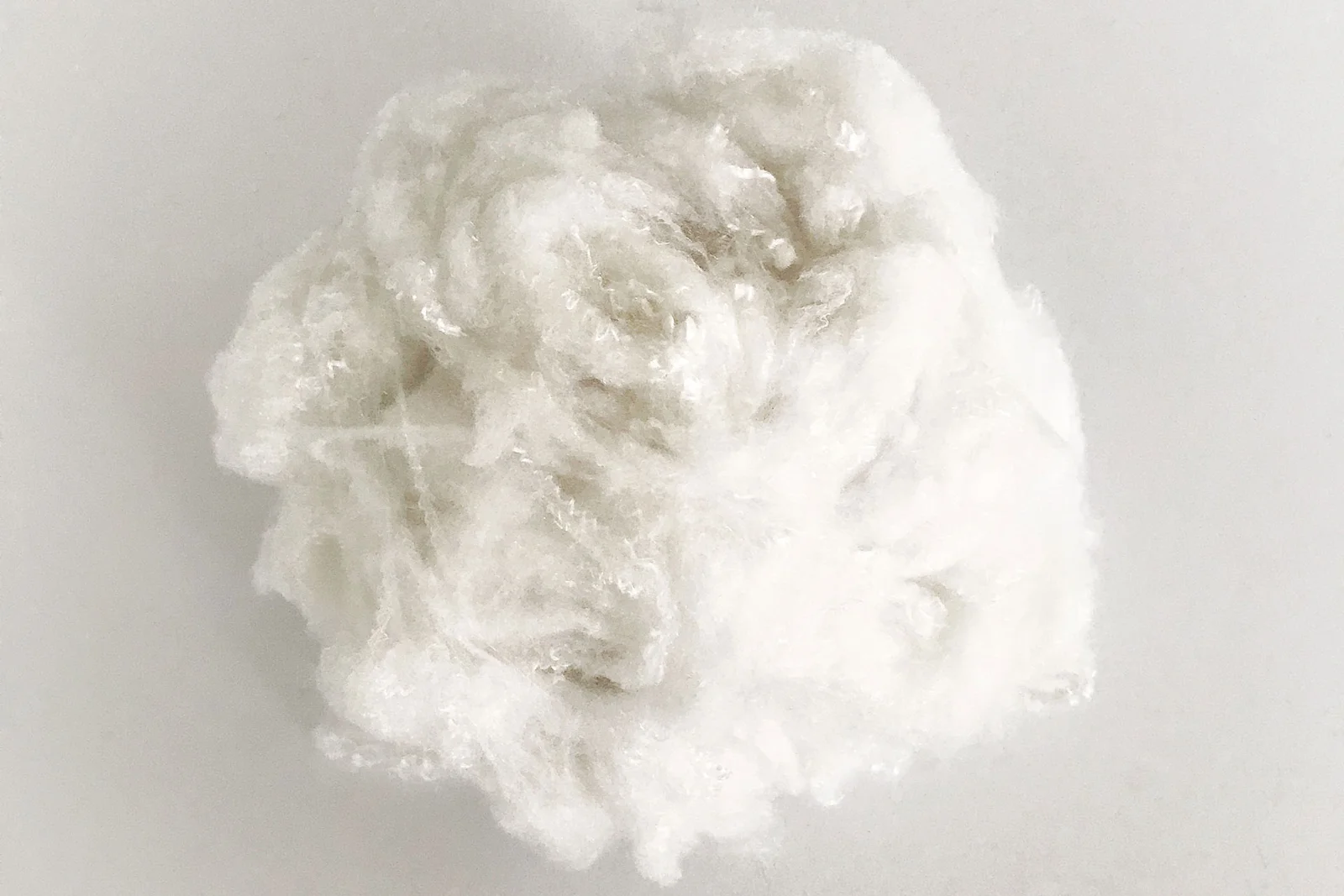

Polyester fiber are a group of synthetic or man-made fiber that, unlike natural fiber such as cotton and wool, are not found in nature. They are produced industrially from petrochemical raw materials or recycled materials with petrochemical origins. Polyester fiber are used not only in the textile industry but also in various non-textile industries. They play a significant role in the production of bedding, carpets, rugs, medical supplies, construction, and road-building materials (geotextiles), among others. The unique features of polyester fiber, such as their light weight, strength, hypoallergenic properties, resistance to natural degradative factors like bacteria, cost-effectiveness, versatility, and availability in various types, have made them popular and widely used. Certain properties of polyester fiber, such as the hypoallergenic and antibacterial features found in hollow and solid fiber, are exclusive to synthetic polyester fiber and are not found in natural fiber.

Factors Affecting the Price of Polyester Fiber in Iran

The price of synthetic fiber in Iran depends on factors such as raw material costs, production and energy costs, transportation costs, market demand, competition among manufacturers, the quality of the fiber according to their applications, and the prices of other production inputs like masterbatch types and necessary chemicals. Additionally, the production method and efficiency, which depend on the knowledge, expertise, and experience of synthetic fiber manufacturers, significantly influence the final product cost. This article briefly examines each of these factors

Types of Production Lines and Technology Used in Synthetic Fiber Production

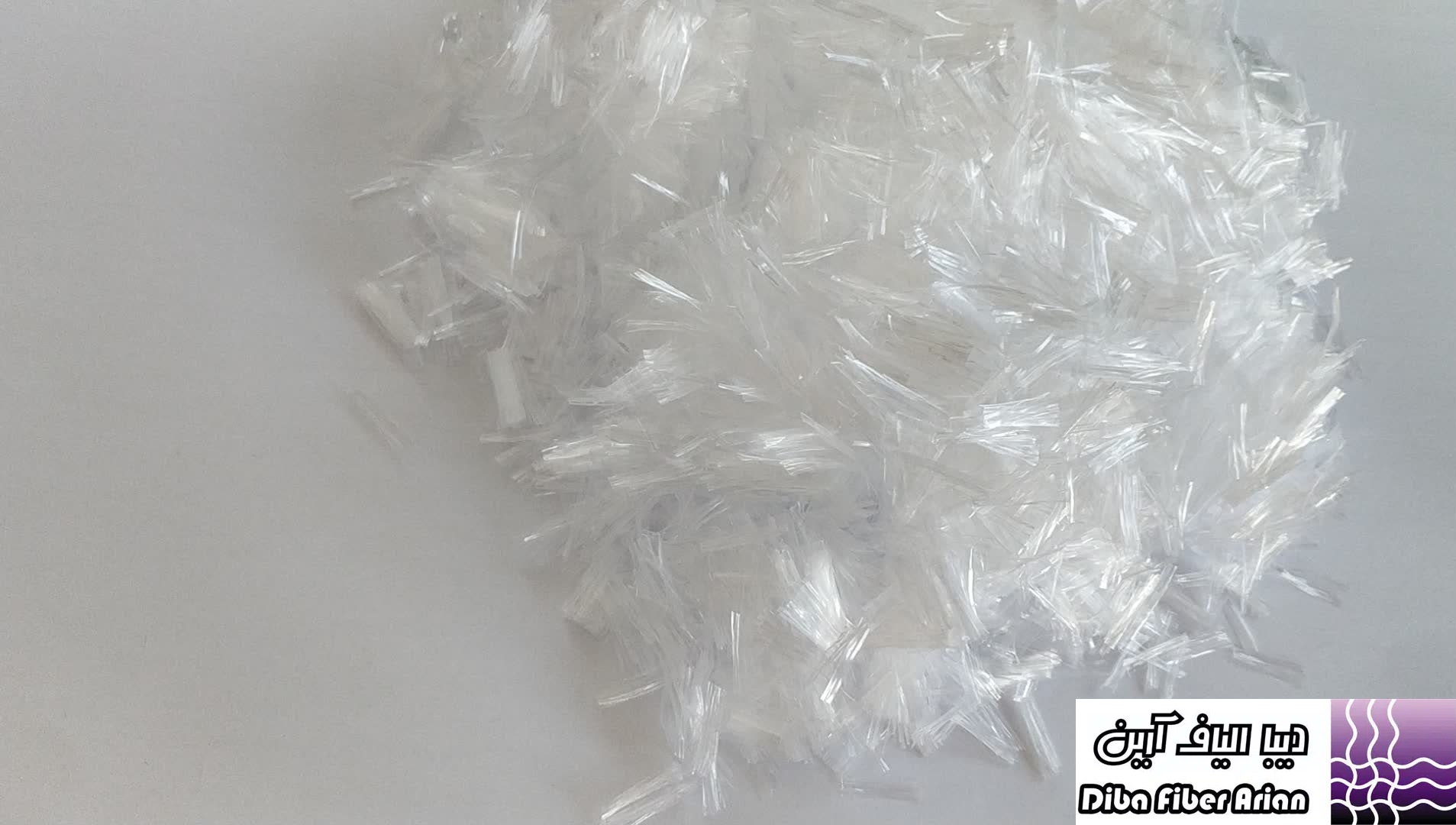

Generally, the basic method of producing polyester fiber is similar across different production lines designed by Chinese-Korean or Western machinery manufacturers, though there are differences in the design of these production machines that directly impact costs. The raw materials for polyester fiber production, sourced from petrochemical industry chips or recycled PET materials (commonly called flakes), undergo several hours of dehumidification preparation. They then pass through a melt spinning process, where they are transformed into very thin and delicate strands by passing through spin packs and various filters. These strands are collected into separate fiber bundles in large bins after passing through quenching and cooling systems, ready for the drawing section. The melt-spun fiber undergo three stages of drawing and pass through a hot water bath before being crimped. In the production of hollow fiber, they are cut to desired lengths and directed to a stenter. For solid fiber, the cutting is done after passing through the stenter. The cut fiber are then baled in 250-kilogram or larger packages, labeled, and prepared for storage or shipment.

polyester synthetic fiber production in iran

Price of Polyester Fiber in Iran is connected to the production lines In Iran, polyester synthetic fiber production lines are generally known by two main names: Pacific lines and Kamkwang lines (named after the two major reference companies that design and manufacture them). Kamkwang lines, utilizing more filters and extruders, experience minimal stoppages in the production process, though the fiber produced are mainly solid fiber in Iran. Due to the nature and technology of Kamkwang lines, cheaper raw materials of lower quality can be used. Producing polyester synthetic fiber with Kamkwang lines generally has a lower cost compared to Pacific lines, which use a single filter and extruder. The production volume of solid fiber in each work shift with both technologies is higher than that of hollow fiber. Thus, solid fiber are generally always cheaper than hollow fiber. Consequently, considering the mentioned factors, solid fiber produced by Kamkwang lines are cheaper than those produced by Pacific lines. It is worth noting that the mentioned production companies currently produce very diverse lines with modern technologies, and the provided explanation is based on the general market practice in Iran for explaining the two main methods of polyester fiber production. Very interesting information about the progress and updates of polyester fiber production lines is available on the websites of these two companies. For example, Shanghai Pacific’s modern production lines can produce over 100 tons of polyester staple fiber, making them the top sellers of such production machinery globally. Similarly, Kamkwang of South Korea exported its first polyester fiber production line to China in 1995, only three years after its establishment. As can be seen, the price of polyester fiber in Iran depends not only on whether they are hollow or solid but also on the technology and type of machinery used in their production

Today, with advancements in technology and the development of artificial intelligence, significant changes have been made in synthetic fiber production lines, increasing energy efficiency and the quality of the produced fiber. In new production machinery, the use of industrial automation has significantly increased, which, by automating processes and intelligently controlling the production process, has minimized the need for human labor in synthetic fiber production. Consequently, with increased production efficiency, the cost of producing polyester fiber has decreased. Furthermore, the use of industrial automation and artificial intelligence in polyester fiber production not only reduces labor costs and production costs but also minimizes human error, which, by reducing waste and increasing production efficiency, helps lower the final product cost.

The Melt Spinning Process and Polyester Fiber Production

The melt spinning and production of fiber require significant energy, including gas, electricity, and water consumption. Apart from human resources, which for classic production lines need about 20 workers per shift, energy costs are also substantial. For the production of 20 tons of synthetic fiber per day, approximately 50,000 cubic meters of gas per year is needed. Conventional and classic machines for producing polyester synthetic fiber generally require 1300 kilowatts per hour of electrical energy, while modern machines need 900-950 kilowatts per hour. Therefore, producing synthetic fiber in countries where energy costs are generally high may not be economically viable compared to countries like Iran, where energy is available to producers at lower prices. This is why European countries have a smaller share in synthetic fiber production, and if they do produce, their synthetic fiber prices are higher.

Moreover, labor wages in Asian countries, including Iran, are significantly lower than in industrialized and developed countries. The wage for an unskilled worker in developing countries is about $200 per month. Additionally, the cost of specialized and technical human resources in developing countries is much lower and incomparable to that in industrialized nations. These factors significantly contribute to reducing the final cost of synthetic polyester fiber and other types of synthetic fiber, creating a more competitive pricing environment for polyester fiber.

As mentioned, the raw materials for producing hollow and solid polyester fiber have petrochemical origins. Therefore, it is logical that raw material prices are cheaper in countries with oil resources than in others. Iran, with its oil resources, can strengthen its competitive advantage in international markets by developing its petrochemical industries and producing the raw materials needed for various industries, including the textile industry.

Price of Polyester Fiber in Iran : production lines

Assuming the price of synthetic fiber production lines is fixed, the cost of establishing and launching a production unit in developing countries is also reduced due to lower prices for industrial land provided by governments. This reduces the initial capital required for synthetic fiber production. Hence, facilitating the entry of foreign investments into the production sector is a consistent policy of governments in developing countries.

The auxiliary sections needed for producing hollow and solid polyester synthetic fiber include oil and steam boilers and their auxiliary facilities, fire suppression systems, air compressors, and cooling and water circulation systems (Cooling Tower, Air Cooler), which are generally supplied with the main machinery,In addition to the cost of raw materials and energy, other factors affecting the price of polyester fiber include auxiliary production chemicals (Auxiliary Agents/ Auxiliary Chemicals) such as various oils, antistatics, and pigments or masterbatches in colored fiber. One of the important applications of polyester fiber is their use in producing various carpets and floor coverings or yarn for various industries, especially the machine-made carpet industry. One of the advantages of synthetic polyester fiber is the ability to produce fiber in various and diverse color shades without limitations. For producing colored polyester fiber for carpet and machine-made carpet production lines, it is possible to add specific percentages of masterbatches or pigments during the raw material preparation stage, at a lower cost than traditional dyeing methods for fiber and yarns. As a result, colored fiber in the desired shade are produced. Therefore, auxiliary materials and masterbatches are factors affecting the price of polyester fiber.

Considering the widespread applications of polyester fiber, the quality of synthetic fiber produced varies according to the final product’s application. Usually, synthetic fiber used in geotextile and waterproofing industries are cheaper than those used as raw materials in bedding or apparel industries. The hollow and solid polyester fiber produced by Diba Fiber Arian are among the high-quality fiber with competitive prices in Iran, widely used in the apparel, furniture, and bedding industries.

Post-Production Transportation and Logistics of Polyester Synthetic Fiber

After the production of polyester synthetic fiber, the baled product must be shipped to customers. The transportation cost directly depends on the distance and the price of energy carriers. Assuming a constant distance from the factory to the customer’s warehouse, transportation costs in industrial countries are much higher than in developing countries for the reasons mentioned above. From an export perspective, the geographical location of the manufacturing country, in general, and the specific case of synthetic fiber, significantly and strategically affects the final cost of the product for customers. Iran, with its advantageous geographical position in the world and its proximity to 15 countries through land and sea borders, has access to Eurasian, Middle Eastern, Southwest Asian, North African, and Eastern European countries.

factors affecting the final Price of Polyester Fibers in Iran

In addition to factors affecting the final price such as raw materials, energy costs, etc., which were previously mentioned, the geographical location of the manufacturing country and access to countries demanding the product play a crucial role in reducing transportation time, a very influential factor in the final cost. For comparison, consider the transportation time of synthetic polyester fiber from Vietnam or China to a country like Azerbaijan. Under the best conditions, the transportation time from origin to destination, including customs procedures and transit through intermediary countries, will be forty days. In contrast, similar goods shipped from Iran to Azerbaijan will take a maximum of one week. Therefore, by modernizing and strengthening the road and rail transport fleet for exporting goods, Iran’s prominent role in supplying various goods, including synthetic polyester fiber, will be further enhanced.

Price of Polyester Fiber in Iran : transporting

The method of transporting the produced goods (in this case, polyester fiber) also significantly impacts shipping costs. Although the geographical location of the buyer determines the best shipping method, generally, sea transport is the cheapest for commercial shipments, while air transport is the most expensive. This is especially important for polyester fiber, which are bulky items. Given that most of Iran’s fiber production is exported to neighboring countries, land transport has the largest share in the transportation of this product.

Diba fiber arian

Diba Fiber Arian, by producing various types of hollow and solid polyester synthetic fiber, has successfully established itself as a reputable brand in domestic and international markets, including the UAE, Iraq, Azerbaijan, Armenia, Tajikistan, Georgia, Russia, Bulgaria, Spain, and more. This success is attributed to understanding the aforementioned factors, utilizing efficient human resources, and producing high-quality fiber at competitive prices.

Today we talked about Price of Polyester Fibers in Iran Thank you for being with us until the end