Synthetic Microfibers and Nanofibers Applications

Microfibers are defined as synthetic fibers with a diameter of less than 10 microns—half the thickness of silk fibers, one-third that of natural cotton fibers, and 100 times finer than human hair...

Synthetic microfibers, first invented and developed in the 1970s, have seen significant advancements in the past decade, with their importance and applications in various industries growing steadily. Following hollow and solid fibers, which are commonly produced in the textile industry, researchers are now focusing on developing much finer fibers with unique properties to meet modern societal needs.

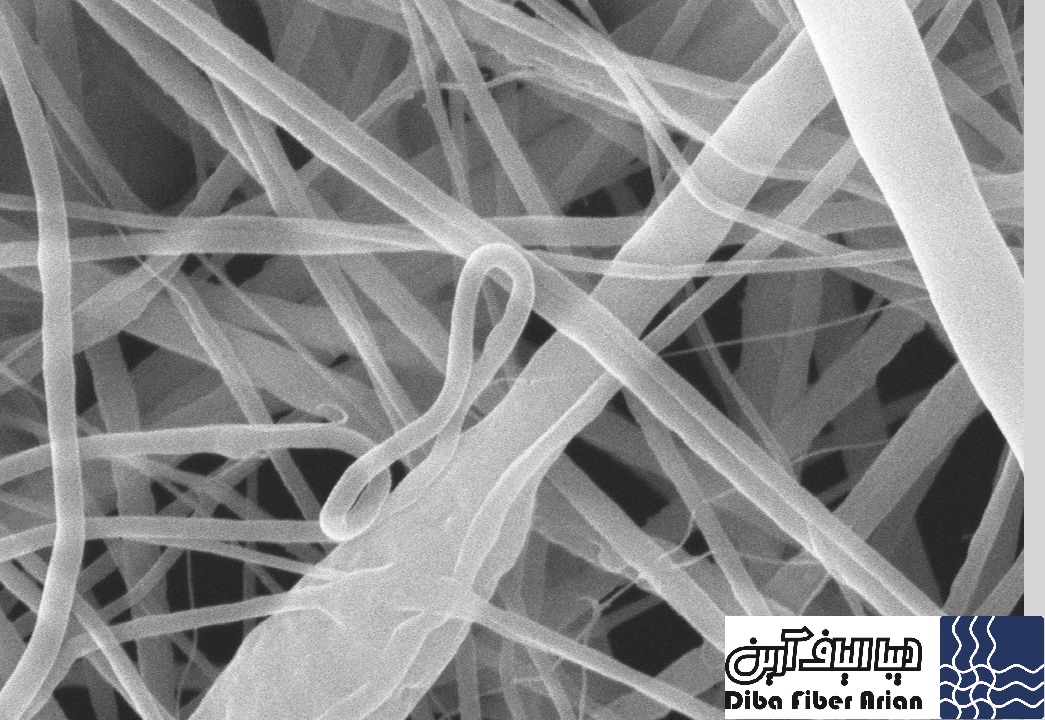

Microfibers are defined as synthetic fibers with a diameter of less than 10 microns—half the thickness of silk fibers, one-third that of natural cotton fibers, and 100 times finer than human hair. Meanwhile, polyester nanofibers produced so far have diameters of around 700 nanometers, making them approximately 7,500 times finer than a single strand of human hair. These polyester nanofibers, developed by Teijin Frontier, were inspired by the foot structure of certain insects. The surface density of fabrics made from these nanofibers is 10 times higher than conventional fabrics, increasing surface friction and making them ideal for products like gloves and holders.

Historical Development and Production Methods

Due to the high demand for fine fiber like silk and the challenges of their costly and limited production, initial efforts to produce ultra-fine synthetic fibers began in the 1970s with Japanese companies, which later introduced commercial microfiber products. By the 1990s, European and American companies followed suit, each launching their own microfiber products. Research into microfibers with high mechanical strength also began in the 1970s, and since then, the number of published studies in this field has grown significantly.

Microfibers are broadly categorized into microfilament fibers and staple fibers. The former can be produced through direct spinning or conjugate spinning, which involves melt-spinning or solution-spinning followed by diameter reduction. For more details on microfiber production methods, refer to the article “A Review of Synthetic Microfibers: Fabrication, Properties, Applications, and Environmental Challenges” published in Journal of Textiles and Polymers, Vol. 11, No. 2, Spring 2023.

Currently, polyester and nylon microfibers are the only commercially available types, though research continues on producing microfibers from other polymers, including cellulose. Unlike polyester and nylon, cellulose microfibers have excellent water absorption, making them suitable for moisture-related applications.

Unique Properties of Microfibers and Nanofibers

As fiber size decreases to micro- and nano-scales, their physical properties change. Reduced diameter leads to lower bending stiffness, tensile strength, and surface friction. However, microfibers offer exceptional characteristics, including:

- Extreme fineness (thinner than the finest silk)

- High coverage and ultra-soft hand feel

- Washability, high strength, and resistance to wind, rain, and cold

- Anti-static properties

- High absorption capacity (up to 7 times their weight)

- Quick drying (three times faster than conventional fibers)

These properties make microfibers significantly more expensive but highly valuable for specialized applications.

Applications in Filtration and Medical Industries

Microfibers are widely used in filtration systems, where they prevent the transfer of fine particles (e.g., microbes) between environments. The filtration industry, including automotive filter manufacturers and medical equipment producers, is expected to be a major consumer of microfibers in the near future. Medical textiles, which require breathability while blocking pathogens, are another key application area.

Polyester Microfiber Spunbond Fabrics

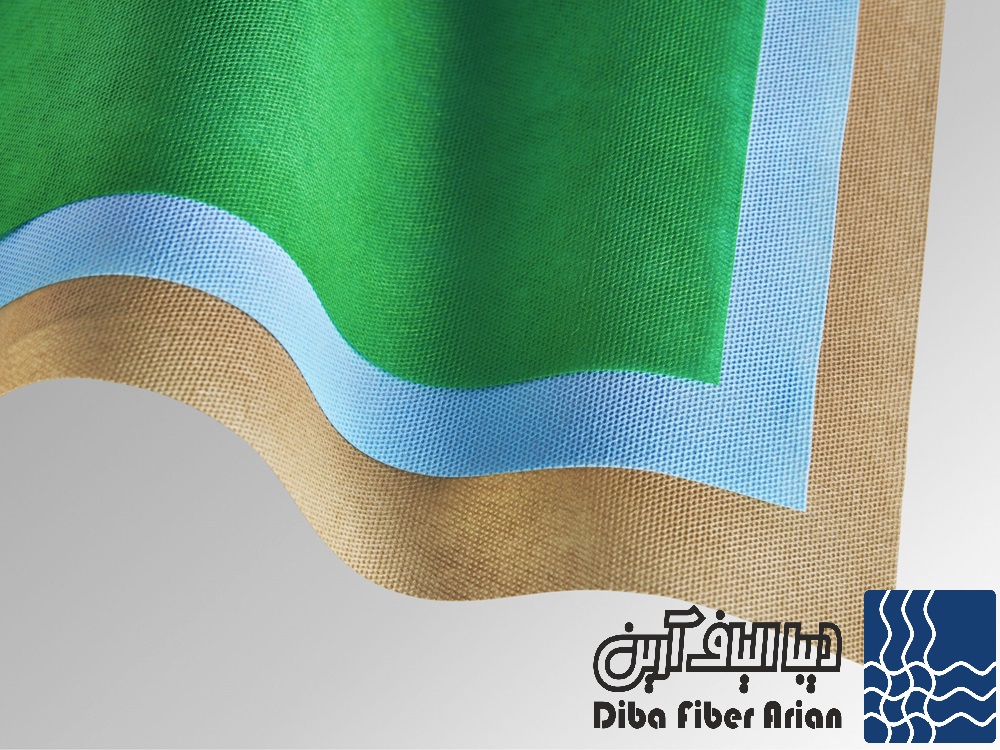

Polyester spunbond microfibers weigh between 170–260 g/m², demonstrating how ultra-fine polyester fibers can enhance product performance and expand industrial applications. By incorporating different polymers, the quality and functionality of polyester microfibers can be further improved. Some additives enhance fabric strength, while others reduce pore size, increasing dust absorption capacity.

Polyester’s inherent hydrophobicity reduces microbial contamination, making it ideal for medical uses. Additionally, adding specific polymers during production can improve properties like melting point and flame resistance, broadening industrial applications.

Advantages Over Natural Fibers

Compared to natural fibers, synthetic fibers like polyester offer better control over fineness, no water absorption, and reduced microbial contamination. With advancements in manufacturing technology, synthetic fibers can now be produced at the nanometer scale.

Sustainability and Future Trends

A major focus in microfiber and nanofiber research is combining biodegradable materials with petroleum-based polymers to create high-strength, eco-friendly products. For example, 1,4:3,6-dianhydrohexitol, derived from natural biomass like corn and wheat, is being used to produce cost-effective polyester nanofibers.

Market Availability and Cost Considerations

Unlike hollow fibers and regular solid fibers—which are competitively priced and widely used in filling materials, nonwovens, and interlinings (thermofused and needle-punched)—microfibers and nanofibers remain less accessible due to higher costs and limited production. However, as demand grows and production methods improve (especially with biodegradable polymers), their availability is expected to increase, leading to lower prices in the near future.

Synthetic microfibers, first invented and developed in the 1970s, have seen significant advancements in the past decade, with their importance and applications in various industries growing steadily. Following hollow and solid fibers, which are commonly produced in the textile industry, researchers are now focusing on developing much finer fibers with unique properties to meet modern societal needs.

Microfibers are defined as synthetic fibers with a diameter of less than 10 microns—half the thickness of silk fibers, one-third that of natural cotton fibers, and 100 times finer than human hair. Meanwhile, polyester nanofibers produced so far have diameters of around 700 nanometers, making them approximately 7,500 times finer than a single strand of human hair. These polyester nanofibers, developed by Teijin Frontier, were inspired by the foot structure of certain insects. The surface density of fabrics made from these nanofibers is 10 times higher than conventional fabrics, increasing surface friction and making them ideal for products like gloves and holders.

Historical Development and Production Methods

Due to the high demand for fine fibers like silk and the challenges of their costly and limited production, initial efforts to produce ultra-fine synthetic fibers began in the 1970s with Japanese companies, which later introduced commercial microfiber products. By the 1990s, European and American companies followed suit, each launching their own microfiber products. Research into microfibers with high mechanical strength also began in the 1970s, and since then, the number of published studies in this field has grown significantly.

Microfibers are broadly categorized into microfilament fibers and staple fibers. The former can be produced through direct spinning or conjugate spinning, which involves melt-spinning or solution-spinning followed by diameter reduction. For more details on microfiber production methods, refer to the article “A Review of Synthetic Microfibers: Fabrication, Properties, Applications, and Environmental Challenges” published in Journal of Textiles and Polymers, Vol. 11, No. 2, Spring 2023.

Currently, polyester and nylon microfibers are the only commercially available types, though research continues on producing microfibers from other polymers, including cellulose. Unlike polyester and nylon, cellulose microfibers have excellent water absorption, making them suitable for moisture-related applications.

Unique Properties of Microfibers and Nanofibers

As fiber size decreases to micro- and nano-scales, their physical properties change. Reduced diameter leads to lower bending stiffness, tensile strength, and surface friction. However, microfibers offer exceptional characteristics, including:

- Extreme fineness (thinner than the finest silk)

- High coverage and ultra-soft hand feel

- Washability, high strength, and resistance to wind, rain, and cold

- Anti-static properties

- High absorption capacity (up to 7 times their weight)

- Quick drying (three times faster than conventional fibers)

These properties make microfibers significantly more expensive but highly valuable for specialized applications.

Applications in Filtration and Medical Industries

Microfibers are widely used in filtration systems, where they prevent the transfer of fine particles (e.g., microbes) between environments. The filtration industry, including automotive filter manufacturers and medical equipment producers, is expected to be a major consumer of microfibers in the near future. Medical textiles, which require breathability while blocking pathogens, are another key application area.

Polyester Microfiber Spunbond Fabrics

Polyester spunbond microfibers weigh between 170–260 g/m², demonstrating how ultra-fine polyester fibers can enhance product performance and expand industrial applications. By incorporating different polymers, the quality and functionality of polyester microfibers can be further improved. Some additives enhance fabric strength, while others reduce pore size, increasing dust absorption capacity.

Polyester’s inherent hydrophobicity reduces microbial contamination, making it ideal for medical uses. Additionally, adding specific polymers during production can improve properties like melting point and flame resistance, broadening industrial applications.

Advantages Over Natural Fibers

Compared to natural fibers, synthetic fibers like polyester offer better control over fineness, no water absorption, and reduced microbial contamination. With advancements in manufacturing technology, synthetic fibers can now be produced at the nanometer scale.

Sustainability and Future Trends

A major focus in microfiber and nanofiber research is combining biodegradable materials with petroleum-based polymers to create high-strength, eco-friendly products. For example, 1,4:3,6-dianhydrohexitol, derived from natural biomass like corn and wheat, is being used to produce cost-effective polyester nanofibers.

Market Availability and Cost Considerations

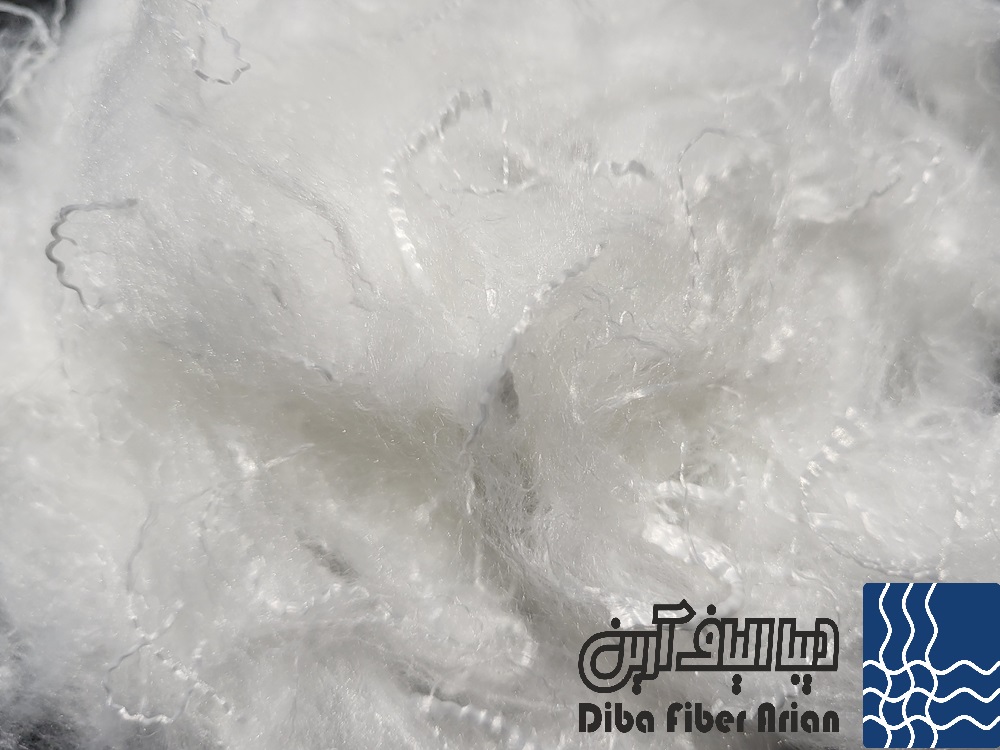

Unlike hollow fibers and regular solid fibers—which are competitively priced and widely used in filling materials, nonwovens, and interlinings (thermofused and needle-punched)—microfibers and nanofibers remain less accessible due to higher costs and limited production. However, as demand grows and production methods improve (especially with biodegradable polymers), their availability is expected to increase, leading to lower prices in the near future.

Diba Fiber Arian

Diba Arian Fibers Industrial Production Company started its activity in Iran in 2004 and is known as the first producer of hollow polyester fibers in this country. Equipped with advanced production machinery and new fiber production lines, this company has the ability to produce all kinds of virgin polyester fibers and recycled solid round, trilobal (star) and halo fibers.

Diba Fiber Arian has a high position in the country’s textile industry with the use of the country’s best fiber production specialists and advanced quality control laboratory. One of the most important advantages of this company is advanced technology in fiber production. These technologies allow the company to produce fibers with excellent quality and special features such as resistance to pressure and heat.

-We look forward to receiving your comments